Artificial intelligence is basically the use of algorithms to simulate aspects of human intelligence and usually also involves independent self-learning of required applications.

According to Intello Labs Asia Pacific Head Tanmay Bhargava, AI-related algorithms need to self-learn from many data points before they become ‘practically usable’.

Intello Labs specialises in using AI to develop image-based solutions in the form of smartphone apps for food product grading and quality monitoring.

“For example, Intello Labs’ AI uses several proprietary artificial neural network algorithms to extract useful features out of a food sample image [when looking at solutions for food safety and quality], while getting incrementally better with each data point,” he told FoodNavigator-Asia.

“[Current] alternatives to AI-based methods for food quality and safety are either manual or lab-based, [and while this] is crucial when it comes to food safety, it is not the best alternative anymore for use cases involving quality and grading.”

Alibaba Cloud, the technology arm of Alibaba Group, also sees AI as one of the ways forward in the food industry, and is capable of benefitting all segments within the food sector.

According to Alibaba Cloud Singapore General Manager Derek Wang: “AI is just like electricity: It can empower every aspect of agriculture and other processes [along the food chain].”

“As an inherently data-reliant and data-rich tool, AI can bring massive benefits for all sectors.

“AI could be used to automate food manufacturing and packaging processes, to inform crop planting and harvesting for more efficient production, and even to help crowdsource consumer feedback to develop new products.”

Watch the video below to see what else Alibaba Cloud has to say about AI.

AI for speed and optimisation

When it comes to brands, Japanese beverage giant Asahi is using AI to forecast the production capacity for its soft drinks business. It started a trial operation in September last year and aims for full-scale AI operation for soft drink production in July this year.

The trial operation had shown that the use of AI could cut down the amount of inventory items and save about JPY$200m (US$1.78m).

“In soft drinks markets, supply and demand levels differ much depending on months (and seasons), so AI is helpful in forecasting production levels,” a spokesman said.

Similarly, machine learning is also required. The spokesman stressed that the AI system would need to ‘learn the way of decision making from experienced workers’ before it can start giving advice on the production levels.

To further improve the accuracy of the AI system, the employees will determine if the output produced by AI is optimum and will make further adjustments again to improve the system.

Swiss food processing technology giant Buhler is also a big proponent of AI. The company counts food and beverage superpowers such as Nestle and Indofoods amongst its clientele, and claims that some 60% of the world’s grain and chocolates is processed through its machines.

Buhler concurred that speed was one of the major benefits that AI can bring to the food and beverage sector.

“In terms of AI benefits, one of the main ones I see is that AI really helps to speed things up,” Buhler Head of Technology, SEA and Pacific Dominique Kull told us.

“For example, it saves a good deal of time when it comes to quality control, such as with our AI-based rice analyser: All that needs to be done is place the rice into the special tray, take a picture with provided app, and send it for cloud-based analysis.

“A detailed report on rice quality, including information on lengths and brokens, can be obtained within seconds, as opposed to traditional systems that require a great deal more time and manual labour.”

“Accuracy is also key, as with human analysis, the larger the volume of analysis, [generally] the more variation is observed with different employees generating different results. With AI and learning algorithms it’s the opposite, the larger the sample size and the more precise and consistent you get over time.”

Another major benefit mentioned was that of process optimisation to reduce food waste.

“Food, from raw material to processed products and finally as a customer meal, generates a huge amount of data – [Using IoT], we can obtain better traceability of the material [as well as] data that could be used to optimise every step along the value chain.

“[As such], AI in combination with big data could be used to optimise these processes, which means to more efficiently use food resources and minimise food wastage.”

AI in food safety

In terms of food safety, Kull added that this was crucial in developing customers’ trust and that AI could bring multiple benefits related to this area.

“Food safety is [of paramount importance], i.e. identifying, reducing and removing harmful contamination and foreign materials from each step of the supply chain. A digitalised control system can identify problems well in advance, preventing threat proliferation in food systems,” he said.

He cited the use of an optical corn-sorting machine equipped with Microsoft cloud technology and special high-speed cameras that can detects aflatoxin inside corn kernels not visible to the human eye.

Aflatoxin is a fungi-produced toxin which is also known to be a dangerous carcinogen.

“The machine performs picture analysis of the grain at industrial speed, analyse those in the cloud and [uses AI to] self-optimise the rejection process. Once the aflatoxin-infected corn kernels are detected, it will automatically remove these with air ejectors,” explained Kull.

A number of Japanese food and beverage manufacturers have also incorporated AI in their manufacturing lines for food safety purposes.

An example is Kewpie, which has started to use convolutional neural network (CNN)-based AI for ensuring food safety since August last year.

Specifically, AI is used to inspect the raw ingredients used in the manufacturing of baby food and delicatessen.

The AI system will first undergo machine learning in identifying the defective items.

“After the AI system has learnt how to identify the non-defective ingredients, it can then be used to inspect identify non-defective ingredients from detective ingredients.

“A signal is entered to the sequencer to control the air gun and blow away defective products,” Takeshi Ogino, Director of Future Technology at Kewpie said in response to queries from FoodNavigator-Asia.

Ogino said that previously, the inspectors checked the ingredients by sight, “but that was a huge burden to their eyesight and so an alternative solution is required.”

The firm is currently developing 20 other AI projects, spanning from energy management, marketing, knowledge management, customer consultation, human resource solutions, and new product development.

Moving forward, it plans to focus the use of AI for the purpose of creating higher customer value.

Wang agreed that AI can assure food safety via tracking and traceability, saying: “Alibaba’s Tmall Global has tapped AI and blockchain to authenticate and verify the supply chain process of products since 2018 in Australia and New Zealand.”

Alibaba and Buhler have also collaborated on an AI-based food safety challenge, where AI experts from around the globe are being invited to compete in search of food safety solutions, such as foodborne disease outbreaks, food fraud or product recalls.

“This contest is the first competition in Asia outside China hosted by Alibaba Cloud Intelligence’s Tianchi platform, and the first worldwide for the agrifood sector,” said Wang.

“[Using Buhler’s global food safety data mining and monitoring service], the contestants will be challenged to create algorithms that can generate automated summaries of discovered food safety incidents at both high relevancy and great precision.”

AI in the future and challenges

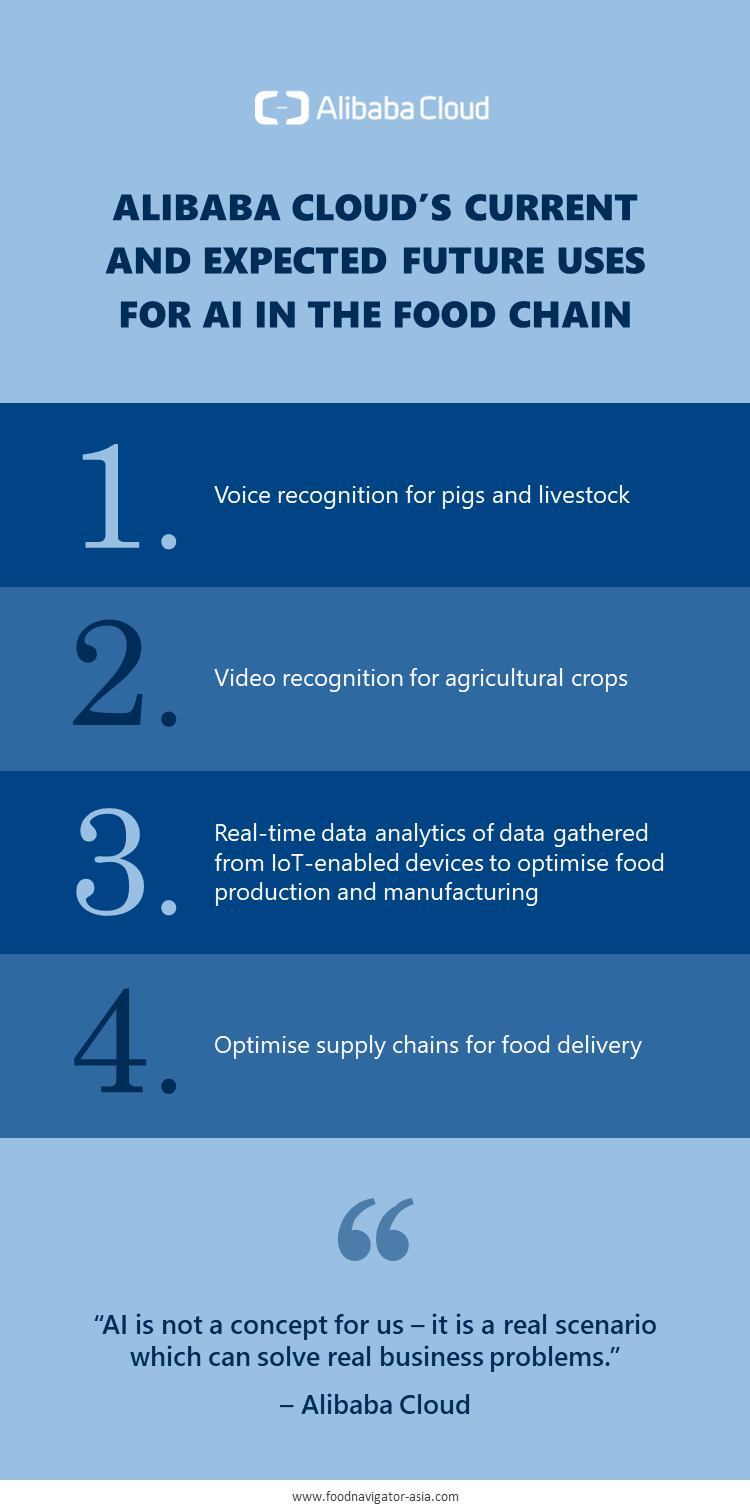

Wang described Alibaba Cloud’s AI solution for the F&B industry, dubbed ET Agriculture Brain, as an application the company expected to extend moving forward.

It uses AI to help hog farmers, or any other agriculture enterprises in China, to better raise livestock and produce crops by using the most-advanced AI tech such as visual recognition, voice recognition and real-time environmental parameter monitoring.

“As with many industries today, the food industry will be a digital-first one, enabled by AI among other technologies,” said Wang

“There is no doubt that AI will play a key role in enhancing smart operations. [Any] improvements we can help drive, especially through technology, will have immense and far-reaching potential to benefit consumers worldwide and is an area we are very keen on exploring.”

“AI is not a concept for us – it is a real scenario which can solve real business problems.”

Bhargava was less optimistic about the AI developments in the Asian F&B industry quite so soon.

“Even though the costs of AI tools and talent have come down drastically in the past decade, it is still high for [most of] the agribusiness sector,” he said.

“[AI-based solutions], talking broadly, also are yet to fully establish a clear value proposition to the industry - most [related] startups here are still in early or scale-up phase. An AI model’s accuracy takes time to reach [commercially viable as] training data sets are hard to build in this sector.”

He added that most early adopters of AI within the food sector have been from America, and less so from Asia.

“[As such], I expect American and European agrifood markets to keep continuing AI [adoption, and this will likely] lead to a widening of gap in tech adoption with respect to the rest of the world.”

“But Asia will start catching up after 3-4 years once AI-based products become more mainstream and low-cost. In the meantime, however, it is upon the Asian startups to adapt to the local needs and take advantage of the open playing field.”