Blockchain has its beginnings in Bitcoin, a ‘peer-to-peer version of electronic cash. The technology was created 10 years ago in 2009 or so to support Bitcoin transaction systems by its founder, a mysterious persona known as Satoshi Nakamoto whose identity remains unknown.

“[Blockchain is essentially] a distributed database that stores data across a network of computers that share information peer-to-peer without the need for a central authority,” explained Alex Vitale, Project Manager at Foodchain, a blockchain technology provider that specialises in food industry applications.

“[Its] digital infrastructure consists of a network made up of ‘nodes’ that are interconnected. Each node is committed to the network’s record keeping by storing an identical copy of the ledger book.

“[This ensures] that data is recorded in a transparent, [incorruptible] way and [is] secured by the use of encryption technology.”

Foodchain is the owner of a ‘Blockchain Technology for Food’ technology offer (techoffer) featured on the online marketplace/website of the Singapore Ministry of Trade and Industry’s Intellectual Property Intermediary (IPI), which features innovative technologies available for licensing or commercialisation. IPI is a government-affiliated organisation focused on promoting open innovation for industry needs.

From a food manufacturer perspective, Singapore food firm SunMoon Food sees blockchain technology as vital for food safety via its traceability through the processing chain.

“Blockchain addresses consumer concern over food safety as it enables real-time tracking of a fruit’s origin from farm to fork. With blockchain, we also strengthen our ability at the B2B level to buy and sell any fruit from and to anyone, anywhere, with no trust issues,” SunMoon Executive Chairman Gary Loh told us.

“[We] implemented blockchain to reap the benefits of food safety, data transparency through product traceability, the tracking of movement product flow and movement of goods.

“One of the things blockchain does for us is to ensure the custody of truth is [out there on the internet] so as to reduce the kind of friction cost [between suppliers, customers and the like that] we face during our business.

“[This is also expected to] encourage [more customers] to buy more of our fruits and manufactured products, as they are better assured of their origin and quality.”

SunMoon uses blockchain technology from partner and provider DiMuto on a pay-as-you-use basis, which Loh said has made the transition much easier and ‘a lot less prohibitive’ for the company.

Watch the video below to find out more:

Blockchain – Benefits for manufacturers

SunMoon first implemented blockchain into its supply chain in November last year, first for premium Fuji apples and later for its packaged Thai Frozen Durian product.

This process involved multiple players along the supply chain. For example, SunMoon trained employees at the supplying packing house for its Fuji apples in China to carry out tagging. They also equipped the facility to scan batch-specific and carton-specific QR codes, as well as capture photographic verification of the apples’ quality.

“Besides blockchaining individual apples, the carton boxes they are packed in are also blockchained using unique QR codes, [which allows for] real-time data capture of the packing status updates of order fulfilments,” said Loh.

“[This gives] an accurate overview of the number of cartons of apples packed, the batch origin of apples in respective cartons, as well as quality when packed.

“This information is then stored on DiMuto’s blockchain platform, and ensures that all trade parties, such as SunMoon, suppliers and customers, have real-time visibility of the apples”

Moving forward, Loh has plans to extend this application to more fresh and manufactured products including citrus fruits, avocadoes and its Sazzy fruit cups range targeted at children, mainly because of the benefits he has observed from the implementation of this technology.

He cited an example where SunMoon managed to successfully tackle a customer complaint using blockchain tracking.

“We had a customer’s customer complain of some quality issues with our apples, and in the past [we] would not have had the ability to check [the tracking data of the apples, e.g. when these were received, which carton they came from, or which order he was referring to]. There was really no visibility.

“[But with blockchain], we just asked the customer to take a picture of the QR code and upload it, and from there found that [the apples were] not from a recent batch. [We realised] that the customer had not put [the products] through a proper cold chain, so it really provided visibility where there was none before.

“[I would say the top three benefits we have seen] are: Product visibility through the supply chain, the environment of trust it allows for us to create with our international business partners as well as reduced miscommunications, as well as increased branding and marketing opportunities,” he said.

Vitale concurred, adding that full benefits are usually observed when blockchain is implemented in a complex supply chain where many moving parts are included.

He cited renowned Italian coffee roasters brand Caffe San Domenico’s use Foodchain’s blockchain technology to enhance the value chain of a specialty, Slow Food-endorsed coffee bean variety native to the Sao Tome Island in West Africa.

“The authenticity of the coffee beans is guaranteed by the local cooperatives that use Foodchain blockchain platform to record information into Caffee San Domenico’s systems,” he said.

“All information on crops, farmers, techniques, processes, batches, certifications and parties involved in the production chain is recorded into a unique identifier and selectively shared across the value chain.

“[This enables] full traceability of the product from the island of Sao Tome to the final customer.”

He added that blockchain technology was also being applied in Malaysia to trace palm oil supply chains in order to enable transparency and promote sustainable practices.

Blockchain – A reflection of consumers’ concerns

Beyond manufacturers, food retailers are also interested in the use of blockchain for monitoring quality management.

China’s e-commerce giant JD.com is one of the platforms that works with brands and manufacturers in tracing the origins and production processes of food products.

Manufacturers can trace its production process by using JD’s Blockchain Open Platform, which was meant to help manufacturers who do not have the capabilities to develop their own blockchain solutions.

At present, 600 brands with 53,000 SKUs products have come on board.

As for the types of information traced, Zhai Xinlei, the head of JD Blockchain Platform and Business, told FoodNavigator-Asia that consumers’ concerns played an important role.

“Consumers are concerned with whether information related to the production process is reliable and transparent, especially when the product passes through a long supply chain, where there are many players involved,” Zhai said.

So what are consumers most concerned with?

Blockchain – A retail strategy?

Besides quality management, blockchain could also double up as a retail strategy, Zhai said.

Citing its recent collaboration with China National Cereals, Oils and Foodstuffs Corporation (COFCO), Zhai said that they tied up consumers’ access to the production information of a brand of cooking oil with a consumer feedback questionnaire.

This means that after the consumers have swipe the QR code of the product to read up about its production process, they could fill up a questionnaire to provide their feedback and views about the product.

In this case, blockchain provides additional value by providing a channel for brands to gather consumer feedback.

On top of that, JD also provides a search filter option, where consumers can quickly sieve out products that employ the blockchain technology.

This further incentivices brands and manufacturers to trace their products with blockchain, since these products enjoy a higher degree of visibility.

“We hope to provide a better retail strategy for the firms who are willing to do product tracing and quality management with us…We will provide extended services for the brands (as they take part in the traceability process), and do product traceability at a deeper and more detailed level,” Zhai said.

Moving forward, he said that JD would continue to hone the performance of its blockchain technologies to further satisfy industrial and consumers’ needs.

The future of Blockchain

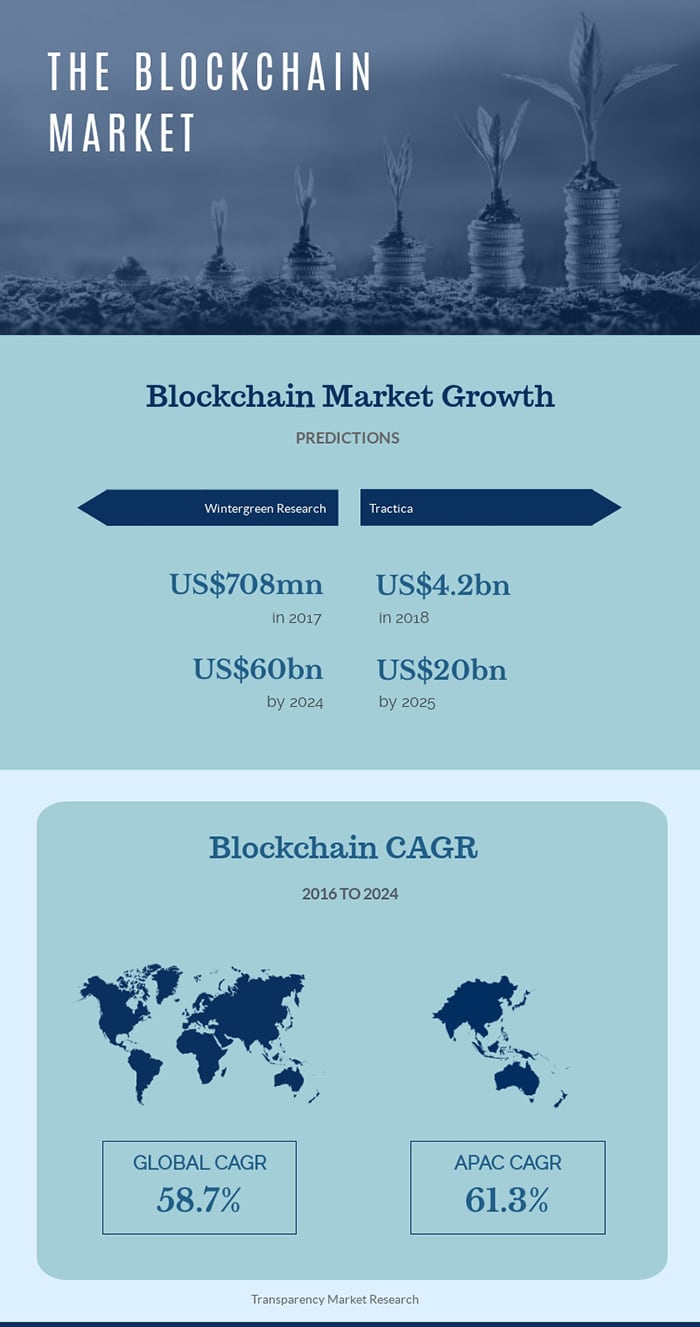

According to Vitale, as smart devices and interconnectivity increase and the Internet of Things (IoT) network flourishes, blockchain importance is predicted to rise.

“[Blockchain] is an essential element in this [IoT-focused] scenario, as its characteristics make it a suitable tool to enable efficient interoperability between devices,” he said.

Additionally, consumer demand for transparency is also expected to encourage further blockchain growth.

“The demand for transparency has forced producers and distributors to seek solutions [in order] to be competitive,” said Vitale.

“[Here], communicating information to customers is key, and blockchain [enables] this in a transparent, secure and efficient way [with] a granular level of accuracy.

“I believe that we are moving towards a data centric world, where everything physical will have a digital ‘twin’, and the information of an item will be more valuable than the product itself.”

He added that the food and beverage industries in several APAC countries are already preparing for full blockchain adoption.

“Countries like Malaysia, Australia and Singapore and are already preparing the ground for the full adoption, especially in the F&B as a driving industry,” he said.